Wowee! We are almost complete with our ModTV’s!! This is the final week of our quilt  along and I do hope you all have been enjoying making these cute retro TV blocks!

along and I do hope you all have been enjoying making these cute retro TV blocks!

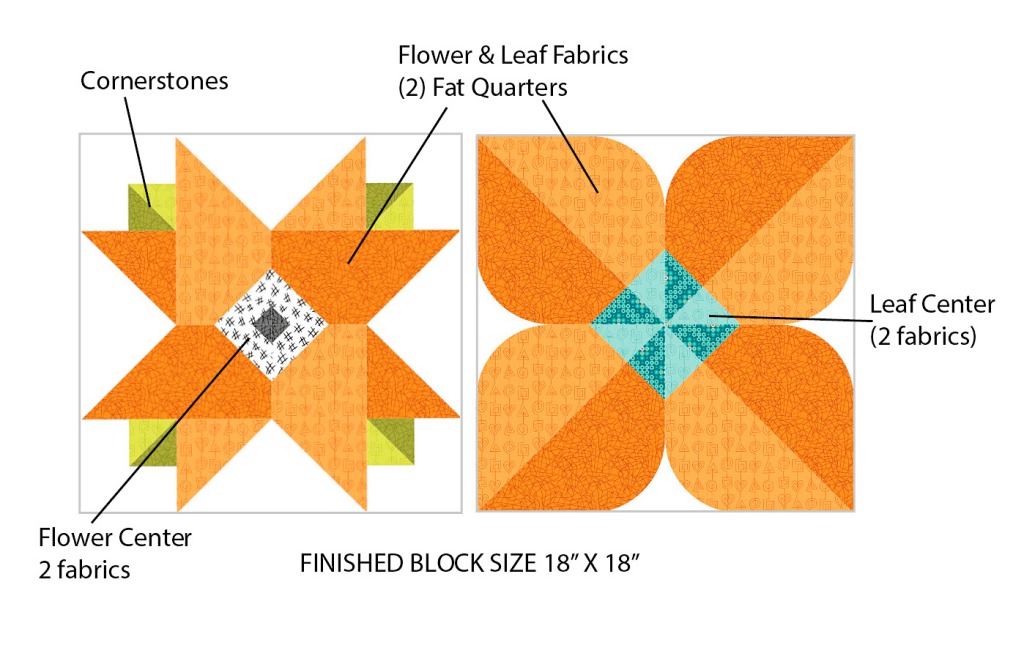

This week – Week #4 – is all about personalizing the TV screen and finishing off your block into a pillow, wallhanging or make even more TV blocks for a fabulous lap quilt! Here’s one of my customer’s ModTV quilt that she made for her husband. She printed all of his favorite TV shows on photo fabrics, added a pocket for the remote control in one of the color bar blocks and voila! – he loved it!

Ok – so by now you should have made at least one ModTV block and it should be trimmed to 12-1/2″ x 12-1/2″. If you need to catch up or need extra help, please refer back to the previous blog posts below. You can also find a weekly companion tutorial video for each week on our Colourwerx YouTube channel !

READ WEEK 1 – GATHER YOUR PATTERN & MATERIALS

READ WEEK 2 – PIECE THE TV & LEGS

READ WEEK 3 – PIECE THE ANTENNA UNITS & COLOR BAR BLOCKS

SUBSCRIBE TO OUR COLOURWERX YOU TUBE CHANNEL

So let’s get started and finish up those cute ModTV blocks!

Check out this week’s video!! You can view the companion You Tube video for this week right here!

Personalize the TV Screen —

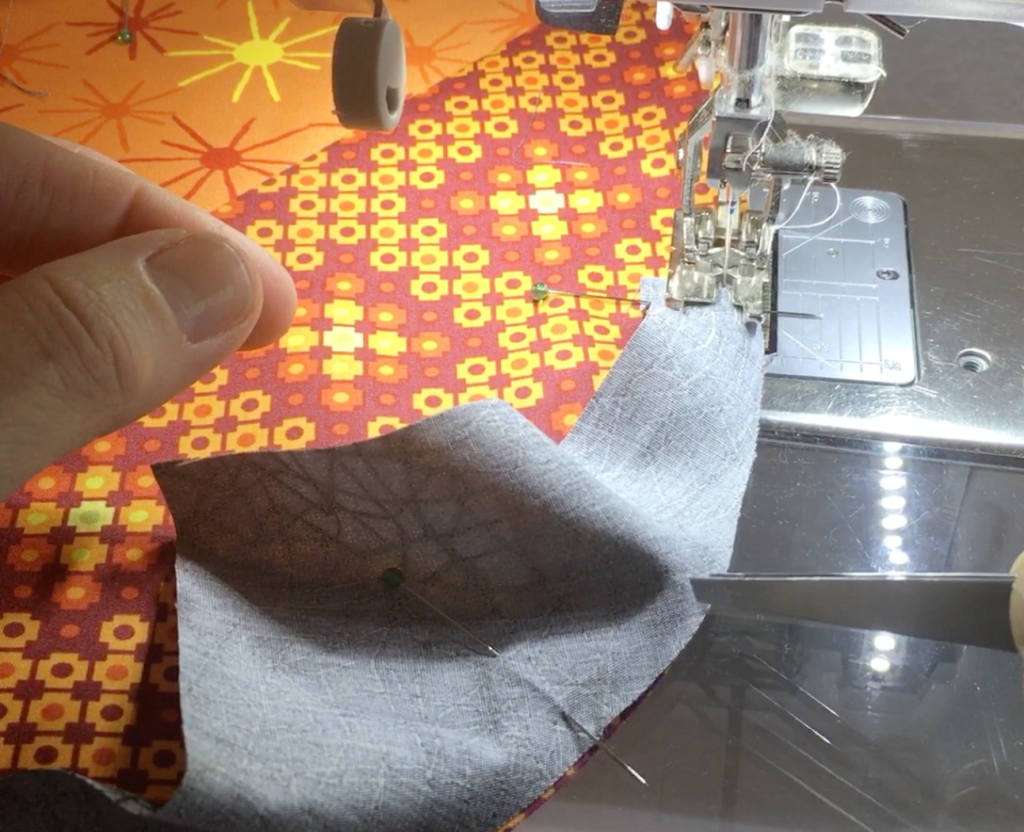

The very last piece to go on your TV block is the TV screen. It is not pieced in but rather fused on with an adhesive fusible web (like Heat ‘n Bond Lite or Steam A Seam II Lite) and then appliqued stitched on.

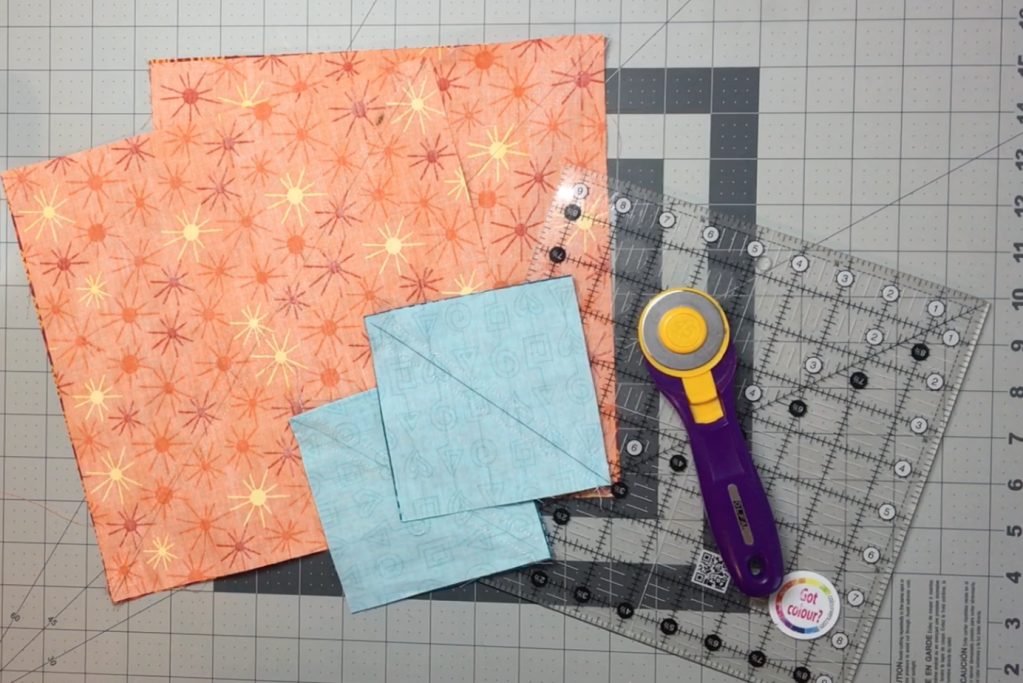

There are several different ways you can choose to personalize your TV screen and therefore make it truly a unique creation. First know that whichever method you choose, you will need both a 5″ x7″ piece of the fabric (or photo fabric) and of the adhesive fusible web.

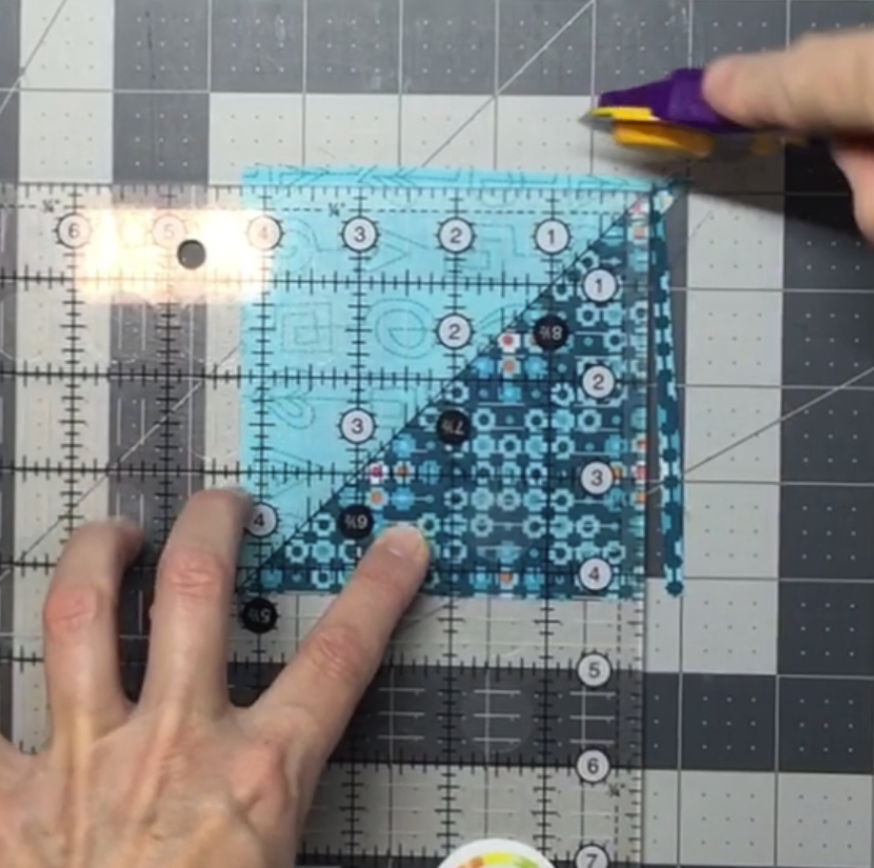

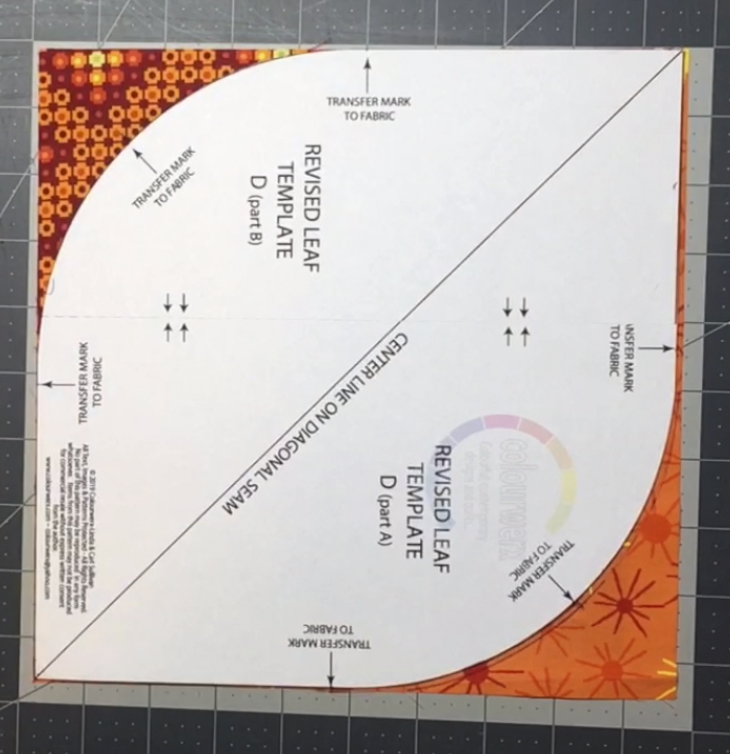

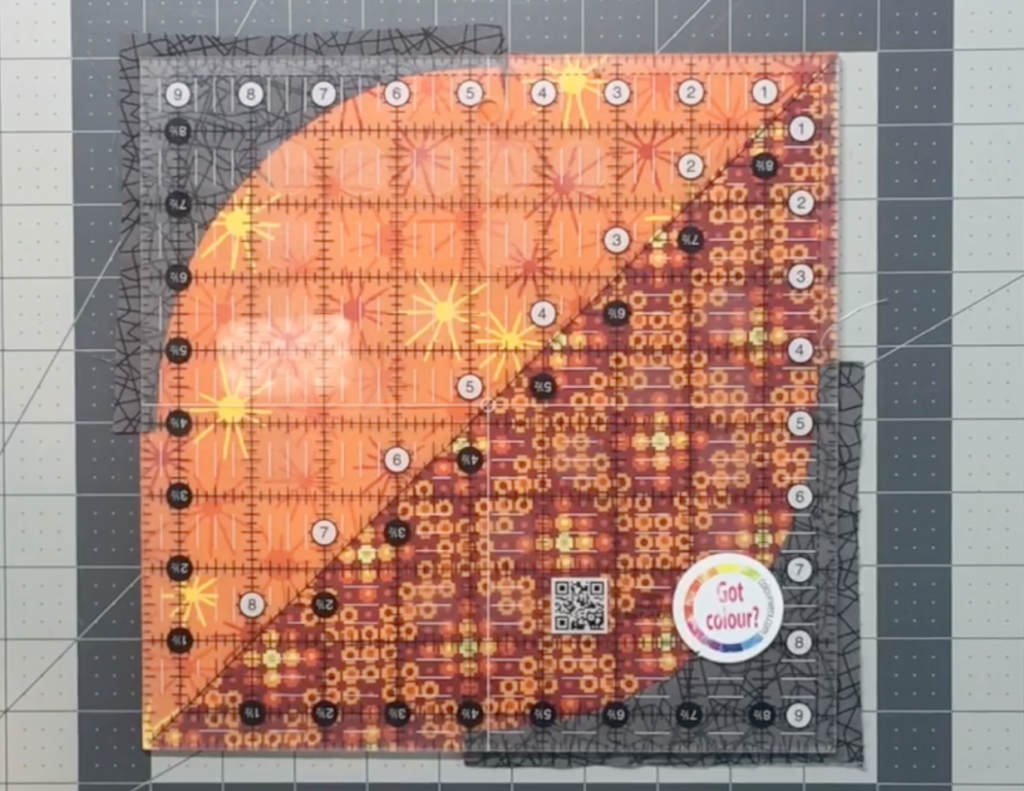

Once you decide what to do, iron the 5″ x 7″ piece of adhesive fusible web onto the WRONG side of the fabric (yes, even the photo fabric), and then trim the piece to 4″ x 6″. You can even follow along in the pattern on page 5 and use a thread spool to round the corners of the TV Screen.

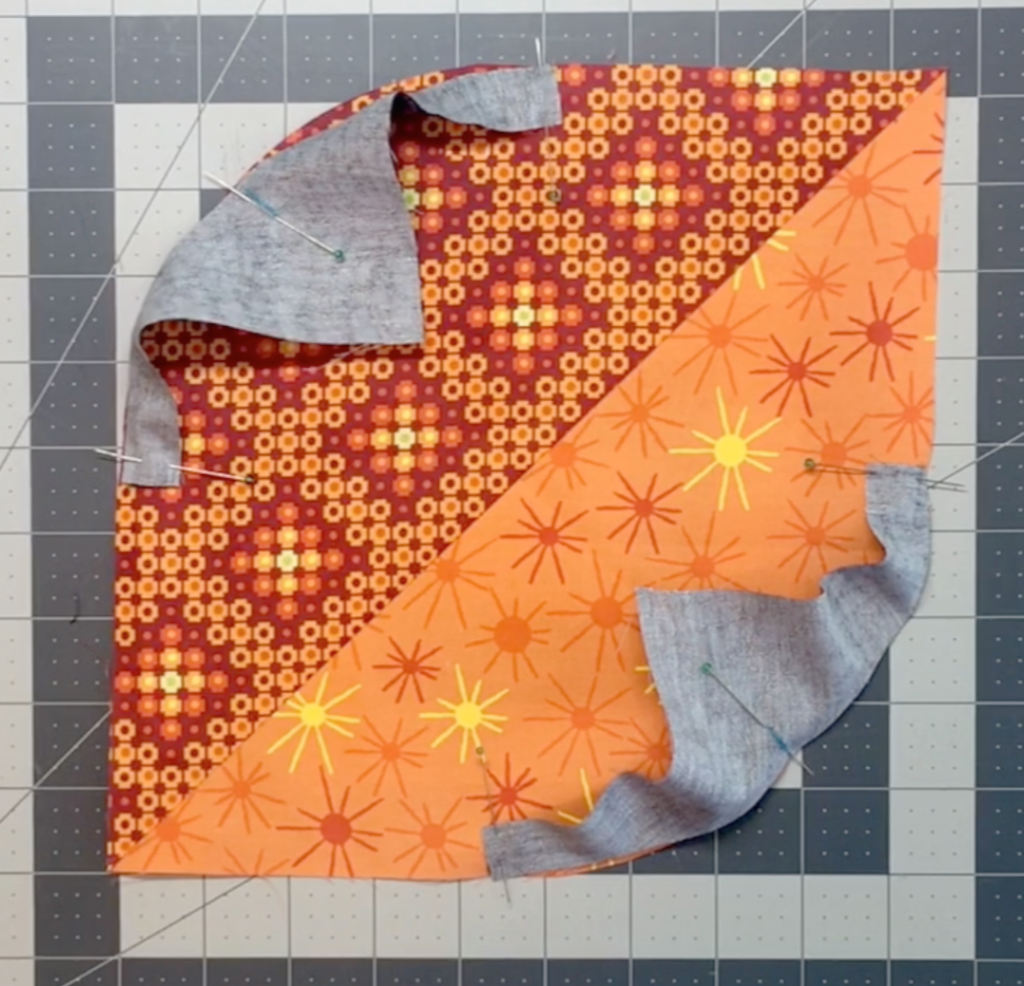

When you are ready, peel the release paper off the backside of the screen, and using a pressing cloth, iron (or fuse) the screen in the center of the TV unit.

Zig Zag stitch around the edges of the screen to secure it to the block.

Here’s a few ideas for you to personalize your TV screens!

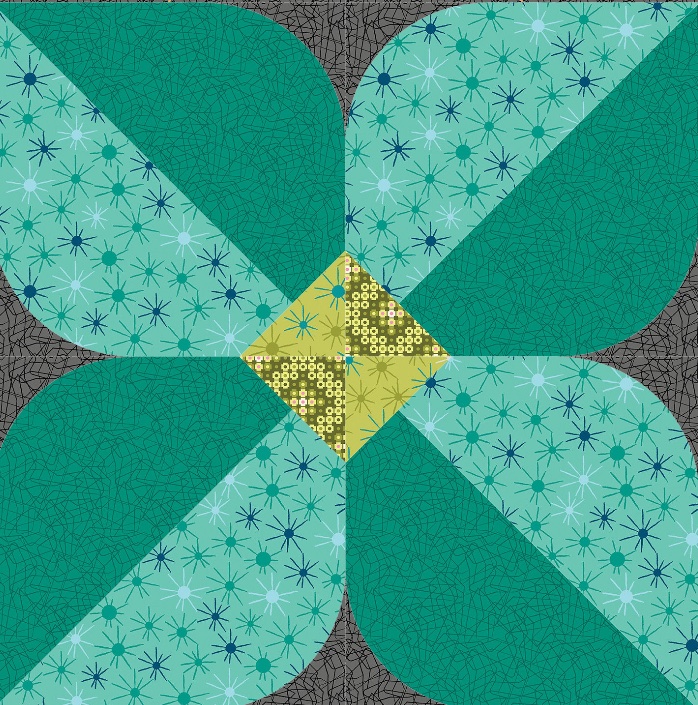

1. Use the same fabric as the background fabric or a similar fabric. The easiest and sometimes the most graphic looking! These blocks are totally fabulous and create the ultimate mid-mod statement!

2. Use a fun stripe or zig zag fabric. If you want to give the look of static running across your TV screen , a fun stripe or colorful zigzag will do the trick! I used this fun colorful wonky zig zag from the Kaffe Fassett Collective!

3. Fussy Cut a Motif from a Licensed Fabric. This is where I think most of us have a lot of fun – fussy cutting around a motif as if this scene is “playing” on the TV set! And there are so many great fabrics to choose from these days: Wizard of Oz!, Star Wars, I Love Lucy!, Star Trek, Cartoons, Cats, Dogs – you name it!

4. Use Photo Fabric for the Ultimate Personalization. I love this idea as it instantly creates a super fun memorial pillow. There are many brands of photo fabric out there – but for me, I find these two brands EQ Printables or June Tailor Computer Printer Fabric to be the most reliable and both are available at your local quilt shop or Joann’s Fabrics.

Here’s a block I made as a gift to Jenny Doan at the Missouri Star Quilt Company!

Here are a few tips when working with photo fabric:

— Resize your photo to a 5″ x 7″ – but make sure when you trim the photo to 4″ x 6″ that you have left ample head room to do so and you wont be cutting off someone’s head ! Also color correct it and “sharpen” it if needed with your photo app or photo program on your computer.

— Before printing on the photo fabric, print the image on a paper – waste a lot of paper until you are sure you have the image correctly sized and framed within the final 4″x6″ margins! Photo Fabric is very expensive and you usually only get 5 or so sheets in a packet.

— When you are ready to print the image on photo fabric, do not print your image using the fine or photo settings on your inkjet printer. This will lay down way too much ink on the photo fabric and your image will appear very dark and may even smudge as it comes through your printer. Just use the regular settings and the photo should print on the phot fabric just fine!

— To heat set the image so the block can be washed, follow the photo fabric manufacturer’s directions. Each company is slightly different! Full disclosure here – I don’t heat set my photo fabric as I don’t wash my blocks. Many of the projects I make are samples or for display only. There are ways though to heat set so you may want to print a test photo and try it first before your final photo printing!

Complete Your TV Block into a Wallhanging or Pillow —

To Make Into a Wallhanging – Once the TV screen has been fused and stitched in place, just add some batting and a backing fabric square that is 12-1/2″ x 12-1/2″. Then quilt the block as desired and bind to create a small wallhanging.

I like to use a straight stitch or even my serpentine stitch (#4 on the Bernina) to stitch lines about a 1/4″ apart. It looks like radio waves or TV signals!

If you did not want to bind your ModTV block, you could frame it using a 12″ x 12″ record album frame from Michael’s Arts & Crafts!

To Make Into a Pillow – As above, once the TV screen has been fused and stitched in place, just add some batting and 2 backing fabric rectangles that measure 9-1/2″ x 12-1/2″. Also purchase a 12″ x 12″ pillow form from your local shop. Place the batting on the wrong side of the block and machine quilt the block using a decorative stitch as described above or just stitch around the TV shape to give the block some texture.

For the backing of the pillow – Turn and press only one 9-1/2″ outer edge (not the 12-1/2” edge though) of each backing piece 1/4” over twice to the wrong side to encase the raw edge. Topstitch down the edge to secure.

Place the two backing fabric units RIGHT SIDES TOGETHER over the MODTV block and stitch around all sides. Turn the unit right side out and poke out the corners. Stuff with a 12” x 12” travel pillow form through the slit on the backside.

This now concludes our ModTV QuiltAlong – send me your pictures so we can see your cute and fun retro TV sets!

Thank you so much for following along and for your continued support! Look for more Colourwerx QuiltAlongs on our Colourwerx Facebook page or on our website under QuiltAlongs!

Until your next colour fix – happy quilting! Linda & Carl xxoo

Whoop! Whoop! We are almost complete with our

Whoop! Whoop! We are almost complete with our

along and I do hope you all have been enjoying making these cute retro TV blocks!

along and I do hope you all have been enjoying making these cute retro TV blocks!