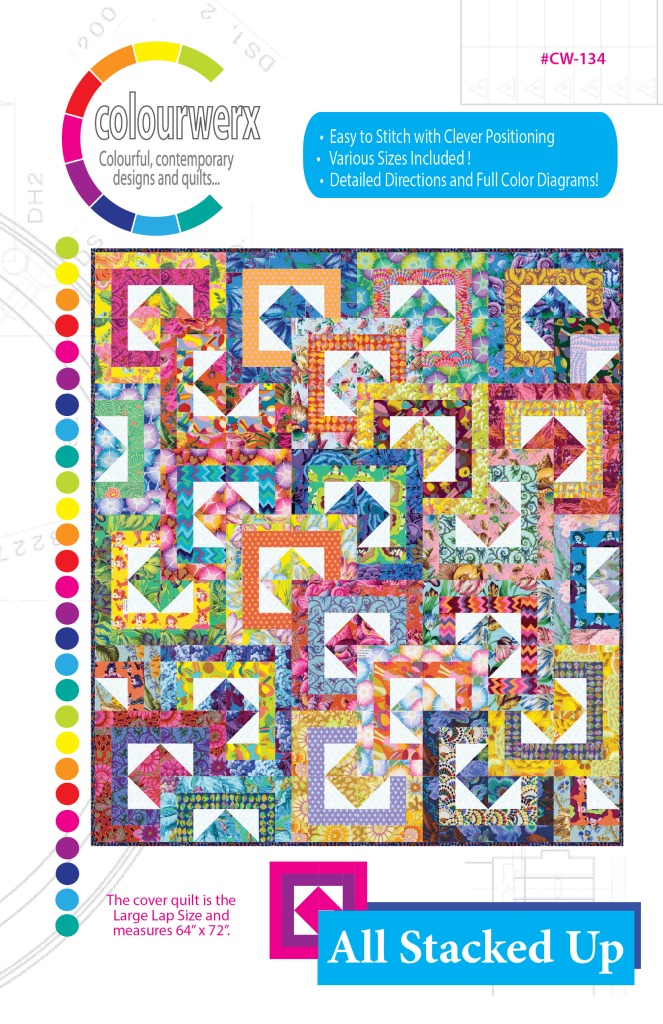

Hello! And welcome to the second week of our super fast and fun new quiltalong: All Stacked Up.

This week is all about piecing the fun All Stacked Up quilt block. By now you should have your fabrics selected and precut according to pages 1 -2 in the All Stacked Up pattern. You should also have a fairly good idea about which fabrics will be paired together. If you are just joining us this week, please refer back to Week #1’s All Stacked Up QAL blog Post right here.

COMPANION VIDEO –

Each week of the quiltalong, I always post a companion video and this week is no exception….If you’d like to view this week’s companion video to Week #2 of the All Stacked Up QAL, view it here:

Set Your Machine Up for Success —

Before we start the piecing fun, I always think it a good idea to set your sewing machine up for stitching success.

Here are few things I always do when starting a new project that requires precision piecing:

• Lift the stitchplate and clean out all of those dust bunnies;

• Change the needle to a new needle – I prefer the Schmetz 75/11 Quilting Needles for precision piecing;

• Thread your machine with a neutral colored 100% cotton , 50 weight thread – my go-to color and thread is #2615 from Aurifil Thread;

• And most importantly, have a good idea of how to stitch a scant 1/4″ seam…

What’s a Scant 1/4″ Seam You Say?? —

A scant 1/4″ seam is a hair less than a full 1/4″ seam.

Many machine manufactuers 1/4″ presser feet are FULL 1/4″ seams . In order to sew accurate 1/4″ seams and have our precision pieced blocks turn out to exactly the finished size they need to, we need to stitch scant 1/4″ seams.

If you’ve ever been frustrated by achieving the perfect seam allowance for quilting then I think I have the perfect little tool for you….it’s the Perkins Perfect Piecing Seam Guide and it works like a dream.

Available at most quilt shops and through Amazon, this little ruler is genius! It is quite simple – it has a hole in the middle and a line that runs end to end of the ruler and through the middle of the hole. The line designates a scant 1/4″ seam allowance.

You place the ruler under your presser foot, drop your needle down into the hole and lower your presser foot on to the ruler. You can now clearly see where you need to line up the fabric edge of your units to achieve a scant 1/4″ seam. Look closely!! – more than likely, it will not be lined up with the edge of your 1/4″ presser foot, but rather just under the edge of the foot and a little bit to the left. Once you study this, you can run a piece of painter’s tape or washi tape along the edge of the Perkins Piecing Guide to mark the stitch plate of your machine for scant 1/4″ precision perfect seam piecing! You are ready to go !

Just a Final Thought on Fabric Pairings —

I know the All Stacked Up pattern says that once you pair fabrics together, they should remain paired together through block piecing, etc….etc…etc…

But really, do they?? Once all of your fabrics are precut and paired up, you do have one final opportunity before piecing to mix up or revise your fabric pairings.

Here’s an example: my first pairing for these fabrics was mixing the green (Fabric A) with the yellow (Fabric B).

But after looking at all of my fabrics, I decided I wanted to mix up the pairings. Now I know from reading the pattern on page 3, that I need (X) amount of units in Fabric A paired with (X) amount of units in Fabric B to make (3) identical blocks. So looking at the pairing on the right side if I wanted to trade out my smaller green Fabric A units for let’s say some smaller lime green Fabric A units, I could! I can mix and match all day – as long as I have the total units for Fabric A and the total units for Fabric B paired in each grouping as specified on page 3 of the pattern.

Let’s take another look at fabric pairings…..here are my first pairings. You can see I’ve got magenta with yellow, green with orange, blue with salmon and so on….

After I precut my fabrics, I revised some of my combinations to create a more color wheel order for the quilt blocks and ended up with these fabric pairings that I like a lot better. In the end, none of my original pairs stayed together and in fact each pair is a completely different combination of fabrics than the other.

So yes, before you start piecing, take a moment to review your fabric pairings ….if you want to switch fabrics from pairing to pairing, heck yes – go ahead ! Just double check that you have the total units needed in the final pairings to make 3 identical blocks.

Piecing the Block —

Referring to the directions in the All Stacked Up pattern on pages 3-4, start by making half square triangles. Add (2) Background Fabric squares to each fabric pairing. Place the square Background Fabrics with the square Fabric A units and make Half Square Triangles – (4) squares in will yield (4) half square triangles out.

Use your square ruler and line up the diagonal line of the ruler on top of the diagonal line of the half square triangle unit to trim and square down each square to the appropriate size.

Discard (1) of the units as you will only need (3) half square triangles for the project.

Piecing the block couldn’t be more simple and chain piecing the (3) individual blocks makes this step go even faster! So go forth and piece all of your fabric pairing to create (3) identical blocks from each fabric pairing following the instructions on pages 3-4 in the All Stacked Up pattern!

That is it for Week #2! I’ll be back next week for Week #3 – our final week- where we’ll be piecing the quilt top together!

Thank you for following along and until then, happy colouricious quilting! L&C xxoo

about stitching your strip sets together ! I love this step in the process as I find it quite relaxing to spend a few afternoons at the machine simple strip piecing the day away – no stress and eazy peazy!

about stitching your strip sets together ! I love this step in the process as I find it quite relaxing to spend a few afternoons at the machine simple strip piecing the day away – no stress and eazy peazy!

Get Your 1/4″ Seam Mojo Going! Now that my machine is ready to go – I always like to test my scant 1/4″ seam. Let’s face it, a 1/4″ seam is not a whole lot of room and alot of things take up space or rob you of that precious seam allowance like thread, pressing, inaccurate cutting, wobbly stitches, thread build up from from seam ripping etc. So a scant 1/4″ seam is what’s really required, and a scant 1/4″ seam is just a hair less than a full 1/4″ seam allowance.

Get Your 1/4″ Seam Mojo Going! Now that my machine is ready to go – I always like to test my scant 1/4″ seam. Let’s face it, a 1/4″ seam is not a whole lot of room and alot of things take up space or rob you of that precious seam allowance like thread, pressing, inaccurate cutting, wobbly stitches, thread build up from from seam ripping etc. So a scant 1/4″ seam is what’s really required, and a scant 1/4″ seam is just a hair less than a full 1/4″ seam allowance.

And that’s it! You are now ready for Week #4 – Cutting the Triangles & Layout.

And that’s it! You are now ready for Week #4 – Cutting the Triangles & Layout. ready!! I really like the Creative Grids brand of rulers! We also have these available for purchase in our Colourwerx shop!

ready!! I really like the Creative Grids brand of rulers! We also have these available for purchase in our Colourwerx shop!